framing nails for concrete

Latest articles

framing nails for concreteThe fence effect of the barbed wire installation can be recognized by the majority of customers, its advantages are as follows: First of all, for some of the original protective device barbed wire because of the convenience of installation, the installation process is very simple, only need to fix the barbed wire column, and then gradually install the barbed wire according to the hook on the barbed wire column.

...

framing nails for concrete 【framing nails for concrete】

Read More

framing nails for concrete

Post time: 23-12-22...

framing nails for concrete 【framing nails for concrete】

Read More

framing nails for concreteIn a rainy climate, it is good to find a place with high dry ground. If there is a rain cloth to hide the rain, so much the better. For field operators, please rest assured that the safety and stability of the mesh, especially in the stacking of paper, slight corrosion will not affect the application.

...

framing nails for concrete 【framing nails for concrete】

Read Moreframing nails for concrete

...

framing nails for concrete 【framing nails for concrete】

Read MoreThrough drawing molding, pickling rust removal, high temperature annealing, hot dip galvanizing. Cooling and other technological process processing. Galvanized iron wire selection of high quality low carbon steel raw materials, after drawing, galvanized and other processes. With galvanized layer, strong corrosion resistance, galvanized layer strong characteristics, electric galvanized iron wire is widely used in construction, highway fence, tie, weaving and other industries.

framing nails for concrete...

framing nails for concrete 【framing nails for concrete】

Read MoreZinc dipping time should be adjusted according to the thickness of wire diameter. The method of adjustment is to use the lead screw above the zinc pot, the length of the distance to the ceramic sinking roller. Thick wire diameter zinc dipping time should be long, fine wire diameter zinc dipping time should be short, zinc dipping length is in the range of 2~3.5m, which is also to reduce the zinc consumption of steel wire, is an aspect of maintaining the uniformity of zinc layer.

framing nails for concrete...

framing nails for concrete 【framing nails for concrete】

Read MoreSince nose touching is an important part of dogs’ social behavior, humans can use this to train them. Experts say that if owners touch their dogs’ noses often when they are young, they will grow up to have softer personalities and be far less likely to hurt people.

framing nails for concrete...

framing nails for concrete 【framing nails for concrete】

Read Moreframing nails for concrete

...

framing nails for concrete 【framing nails for concrete】

Read Moreframing nails for concrete

...

framing nails for concrete 【framing nails for concrete】

Read MoreBut there are some necessary precautions in the production of galvanized wire. Remove all tools and piles on the work site and equipment that hinder activities, and slowly put the wire into the cylinder during pickling to prevent acid splashing on the body. When adding acid, the acid must be slowly poured into the water. Do not pour water into the acid to prevent acid spillage and injury. Workers should wear protective glasses when working. Then in the handling of wire and other items, it is strictly prohibited to push hard.

framing nails for concrete...

framing nails for concrete 【framing nails for concrete】

Read More

Popular articles

- Both sides of the galvanized welding net exposed can not be more than 2mm, so as to be qualified. And in the welding mesh of each warp and weft wire cross place, must be welded very firm, and if you want to welding very firm, both sides must have some warp and weft wire out, and the length must be controlled within two millimeters. From the mesh distribution is not uniform, galvanized is not uniform, but also to see whether the welding mesh is qualified standards.

Post time: 25-05-23- Choose a cage with a reasonable structure, such as a tray under the cage, so that the dog can relieve itself directly inside the cage. It’s easy for the owner to clean up.

Post time: 19-05-23

Latest articles

-

Twine: Twist two or more wires into a double wire rope and then wrap the twine around the double wire. It’s called a straight twist cord which is the common double strand cord.

-

Electro galvanizing shaft wire direct is in the electroplating tank through the current unidirectional zinc gradually plated on the metal surface, production speed is slow, uniform coating, thin thickness, usually only 3-15 microns, bright appearance, poor corrosion resistance, generally a few months will rust. Compared with hot dip galvanizing, electric galvanizing has lower production cost. The difference between cold galvanizing and hot galvanizing: the difference between cold galvanizing and hot galvanizing is that the amount of zinc is different. They can be identified from the color. The color of cold galvanizing is shiny silver white with yellow. Hot dip galvanized shiny hair white.

-

The material of small hexagonal mesh is the same as that of other hexagonal mesh, which is generally made of low carbon steel wire, stainless steel wire and galvanized steel wire as raw materials by the hexagonal mesh machine.

-

Post time: 13-02-23 -

-

Links

Practical Applications

1. Heat Sealing Machines These are among the most common types of bag seaming machines. They utilize heat to melt the edges of the bag material, allowing the two sides to bond together as they cool. Heat sealing is particularly effective for plastic and some synthetic materials, providing a reliable closure that is both airtight and waterproof.

2. Walking Foot A walking foot can help prevent layers of leather or vinyl from shifting as you sew, resulting in straight seams and a professional finish. This feature is particularly beneficial for users working on projects that involve multiple layers.

As the name hi-speed suggests, these machines operate at significantly higher speeds compared to standard sewing machines. They can reach speeds of up to 5000 stitches per minute, which optimizes production times and increases efficiency in manufacturing settings. This high-speed capability makes them invaluable in mass production environments where time and precision are critical.

Additionally, sailmaker machines often come equipped with specialized needles designed for heavy-duty sewing. The needles used in these machines are robust and capable of piercing multiple layers of fabric, as well as withstanding the abrasive nature of materials often used in sail construction. Furthermore, many machines include adjustable stitch lengths and widths, enabling sailmakers to customize their stitches based on the specific requirements of each project.

sailmaker sewing machine

Choosing the Right Heavy-Duty Quilting Sewing Machine

Benefits of Using a Compound Feed Heavy Duty Sewing Machine

Before making a purchase, consider factors such as stitch types, durability, ease of use, and customer reviews. Investing in a high-quality machine can ensure years of successful sewing projects.

In the contemporary landscape of manufacturing and packaging, the efficiency and reliability of machinery play a crucial role in meeting production demands. One such machine that has gained significant attention is the bulk bag sewing machine. Designed specifically for the production of bulk bags, also known as FIBCs (Flexible Intermediate Bulk Containers), these machines have transformed the way manufacturers handle large quantities of material, offering speed, precision, and durability.

Quality is a key concern for any textile manufacturer. Overlock sewing machines contribute to higher quality outputs by creating durable seams that withstand stress and movement. The overlocking stitch is inherently stronger and more flexible than a standard straight stitch, making it ideal for garments that require stretch, such as athletic wear or fitted clothing. This ensures that the end products do not only look good but also last longer, reducing return rates and improving customer satisfaction.

FIBC sewing machine heads are specialized machines designed to handle the unique requirements of sewing large, often heavy-duty fabric structures. These heads utilize advanced technology to provide precise stitching for FIBC bags, which are typically made from woven polypropylene or other synthetic materials. The sewing process must ensure that the bags can withstand significant weight and environmental pressures, making the machine head's performance crucial.

First, let me clarify this question I frequently bump into: this is a type of sewing machine designed to handle tough fabrics and thicker materials such as denim, canvas, and leather - better.

Are you looking for a heavy duty sewing machine that will sew through leather like butter? Will you be sewing materials like denim or draperies? Or do you need a machine that will handle multiple layers of fabric at once? These type of fabrics and projects require a solid machine built for heavy jobs, unlike some of the more inexpensive beginner sewing machines.

A coverstitch machine is designed primarily for hemming and finishing the edges of knit and stretchy fabrics. It produces a distinctive double-stitch on the front side and a serged finish on the back, effectively combining a professional look with durability. This type of machine is exceptionally beneficial for creating garments that require flexibility, such as T-shirts, leggings, and activewear. The coverstitch allows for easy movement of fabric without compromising the integrity of the stitches, rendering garments that are comfortable to wear.

- Foot and Needle Options Ensure the machine accommodates various foot types and needle sizes, as this flexibility can greatly enhance your sewing experience.

3. Speed and Efficiency These machines are designed for high-speed operation, significantly reducing production time and costs in large-scale manufacturing environments.

Investing in heavy duty sewing needles is a smart choice for both amateur and professional sewers alike. Whether working on fashion apparel, home decor, or leather crafts, these needles provide the reliability and strength necessary for tackling the toughest of projects. Understanding their features and applications will not only enhance the quality of your stitching but also expand your creative possibilities in the world of sewing. So the next time you reach for your sewing kit, make sure to include heavy duty needles in your arsenal!

The Long Arm Zig Zag Sewing Machine A Seamstress’s Best Friend

In summary, a heavy-duty upholstery sewing machine is an invaluable asset for anyone involved in upholstery projects. The combination of power, versatility, and durability cannot be underestimated. Whether you're reupholstering a vintage chair or creating custom furniture, using a heavy-duty machine ensures that your sewing tasks are completed efficiently and to a high standard. Investing in a quality machine not only enhances your skill set but also inspires creativity, allowing you to pursue your upholstery projects with confidence and ease.

Conclusion

Additionally, the durability of these machines means that you can expect a long-term investment. While they may come at a higher upfront cost compared to basic models, their robust design and powerful performance ensure they stand the test of time, making them worth every penny.

If you're looking for the best in professional-grade heavy-duty machines, the Juki TL-2010Q is often recommended by experts. With a powerful motor and a maximum sewing speed of 1,500 stitches per minute, it is designed for efficiency and precision. The TL-2010Q is equipped with a large extension table, ideal for quilting projects, and features an automatic needle threader. Its industrial-grade design guarantees stability and strength, making it a favorite for quilters and those working with heavy materials.

Some thinner materials will require a special kind of stitch and also a lower ironing temperature. Thicker materials might also need to be sewn in layers. This process requires a powerful heavy duty sewing machine that can easily reach through the material without breaking or bending the needle.

One of the key advantages of a long arm heavy duty sewing machine is its extended arm. This feature allows you to work on larger projects such as quilts, curtains, and upholstery with ease. The extra space gives you more room to maneuver the fabric and makes it easier to sew straight and even seams. This is particularly useful when working on bulky or intricate designs that require precision and accuracy.

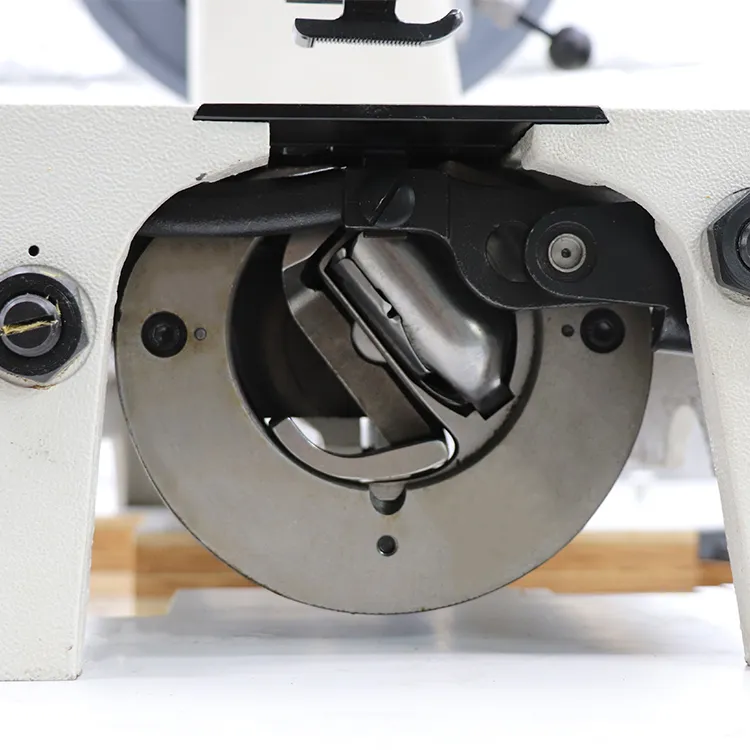

In the world of textile manufacturing, few innovations have had as profound an impact as the Union Lockstitch sewing method. This invention, which revolutionized the way fabrics are joined together, plays a critical role in various applications, from garment production to upholstery and beyond. The Union Lockstitch is a specific type of lockstitch created primarily for its durability, versatility, and efficiency.

One of the most significant advantages of automatic machine sewing is its ability to boost production speed. Traditional sewing methods often require skilled laborers to complete each step of the sewing process, which can be time-consuming and labor-intensive. In contrast, automatic sewing machines can perform numerous tasks in a fraction of the time. For example, automated machines can sew hems, attach buttons, and finish seams all in one pass, drastically reducing the time required to produce garments. This efficiency not only meets the increasing demand for faster turnaround times in the fashion industry but also contributes to cost savings.

to modify the pace of your machine to fit your specific need. Set the speed to the “Max” if you want to sew quickly or to “Min” if you are teaching someone or if you need to sew something slowly and with precision. Every seamstress has different likes and from my experience, I use this feature all the time and it is one I wouldn’t want to do without.

5. Ease of Use and Maintenance Look for models designed for easy threading and maintenance. Machines that are straightforward to use will minimize downtime and ensure that you can focus on creating rather than troubleshooting.